Filter Press Cloth Manufacturer in China

Looking for reliable filter press cloths made in China? Look no further! We manufacture top-performing filter cloths to meet your specific filtration needs and budget.

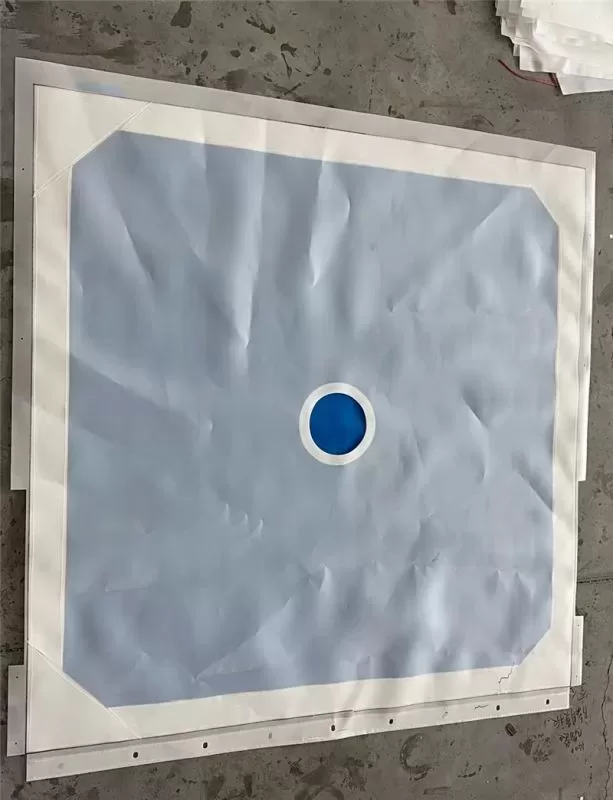

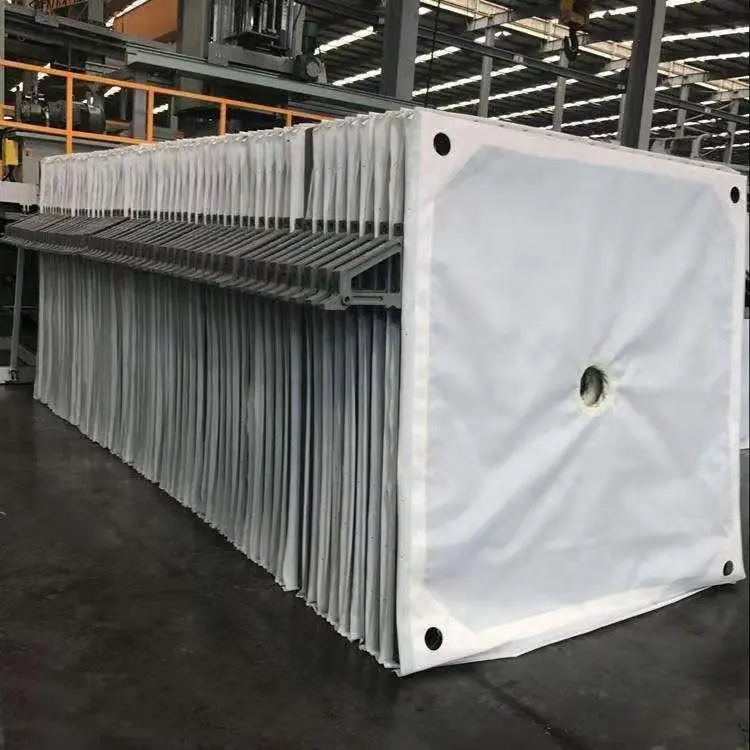

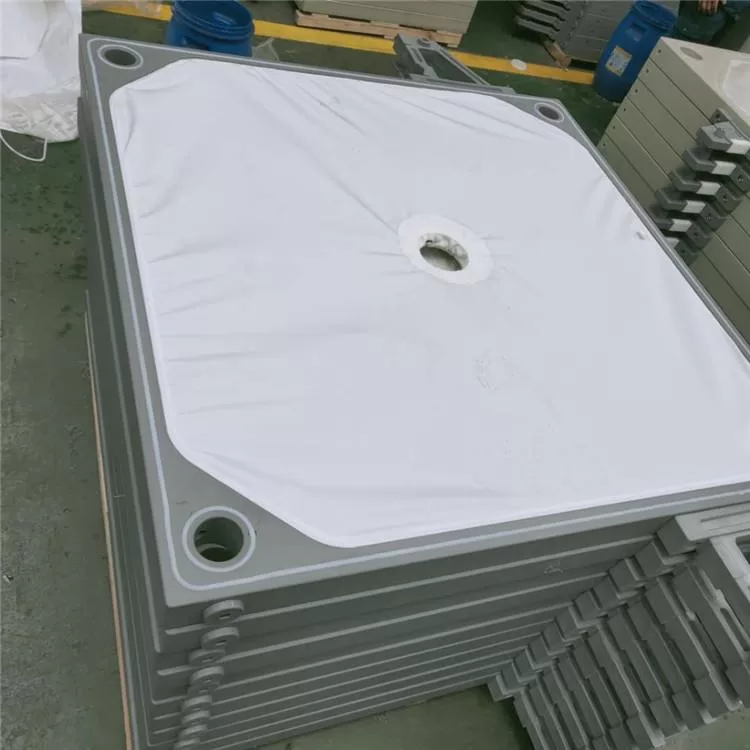

Our Filter Press Cloths & Media

Manufacturer direct sales at very Competitive Prices. Custom materials, sizes and specifications for your filtration needs. Door to door delivery by Express or Sea.

Filter Press Cloth Yarns & Materials

| Type of Fabric | PH | Temperature | Characteristics |

|---|---|---|---|

| Polypropylene (PP) | 2-12 | up to 90°C | Polypropylene boasts good tensile strength, allowing it to handle significant loads while remaining lightweight. It excels in environments with organic and mineral acids, solvents, and alkalies. However, high temperatures and concentrated solutions of nitric and chlorosulphonic acids, sodium hydroxide, and potassium hydroxide can damage polypropylene. |

| Polyester (PET) | 2-9 | up to 150°C | Polyesters can withstand exposure to a wide range of acids, oxidizing agents, and organic solvents. However, concentrated sulfuric and nitric acids are too strong and will cause damage. Additionally, strong alkalies can dissolve polyesters. |

| Nylon | 2-8 | up to 120°C | Strong and alkali-resistant, nylon offers excellent performance in many applications. However, it’s susceptible to degradation by mineral acids and oxidizing agents. This breakdown process happens faster at higher concentrations and temperatures. |

| Cotton | 3-10 | up to 105°C | Cotton boasts good abrasion resistance and mechanical strength, making it suitable for long-lasting use. However, cotton is susceptible to rot, mildew, and shrinkage. |

| Acrylic | 4-5 *Depending on other factors | 125 to 135°C | Acrylic fibers offer excellent resistance to organic solvents, most oxidizing agents, mineral acids and organic acids. However, their resistance to alkali is only fair, and they will dissolve in concentrated sulfuric acid. |

Filter Press Cloth Resistance Comparison

| Type of Fabric | Tensile Strength | Abrasion Resistance | Chemical Resistance | °F | °C | PH | |||

|---|---|---|---|---|---|---|---|---|---|

| Acid | Alkali | Cont. | Surge | Cont. | Surge | ||||

| Polypropylene (PP) | Excellent | Good | Excellent | Excellent | 190 | 190 | 90 | 90 | 2-12 |

| Polyester (PET) | Excellent | Excellent | Good | Fair | 275 | 325 | 135 | 150 | 2-9 |

| Nylon | Excellent | Excellent | Poor | Excellent | 200 | 250 | 90 | 120 | 2-8 |

| Cotton | Good | Average | Excellent | Poor | 180 | 225 | 80 | 105 | 3-10 |

| Acrylic | Very Good | Average | Very Good | Fair | 260 | 280 | 125 | 135 | |

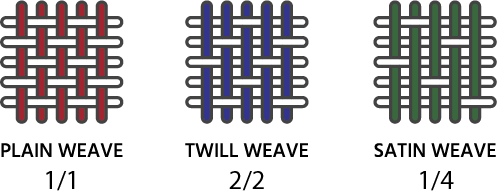

Filter Press Cloth Weaving Methods

- Plain Weave: The filling yarn alternates over one and under one warp yarn, resulting in a simple and balanced fabric with a flat surface.

- Twill Weave: The filling yarn interlaces with at least two warp yarns at a time, diagonally across the fabric. This creates a more flexible structure compared to a plain weave. As a result, solids are less likely to get trapped within the gaps between yarns, offering a smoother surface.

- Satin Weave: This weave features warp yarns that pass over multiple filling yarns, resulting in a flexible fabric with a smooth surface that releases cakes effortlessly.

Request a Quote for Filter Press Cloth

Get the perfect filter press cloth for your needs! Contact ChinaFilter today. Our experts are happy to answer your questions and provide a personalized quote.