Choosing the optimal filter cloth is crucial for efficient and cost-effective operation in sand washing, coal washing, and mud pressing industries. The ideal cloth needs to strike a balance between capturing desired particles, maximizing filtrate clarity, and withstanding the demanding conditions of these processes.

This guide explores key factors to consider when selecting a filter cloth for your specific application:

1. Common Filter Cloth Material:

- Polyester (PET): Offers excellent chemical resistance, good abrasion resistance, and dimensional stability. Ideal for sand washing and dewatering applications with neutral or acidic slurries.

- Polypropylene (PP): Economical option with good chemical resistance to alkalis and organic solvents. Suitable for mud pressing in wastewater treatment.

- Nylon (PA): High strength, elasticity, and abrasion resistance. Well-suited for coal washing due to its ability to handle harsh environments.

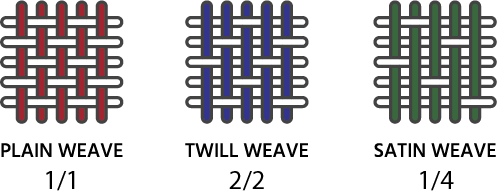

2. Weave Pattern:

- Plain weave: Simplest and most economical option, offering good filtration efficiency for larger particles (sand washing).

- Twill weave: Offers a balance between filtration efficiency and blinding resistance. Suitable for sand washing and coal washing with finer particles.

- Satin weave: Provides a smooth surface for minimal cake release issues. Ideal for mud pressing applications with sticky materials.

3. Mesh Size:

Mesh size refers to the number of openings per linear inch. A finer mesh size captures smaller particles but reduces flow rate.

- Sand washing: Typically uses coarser mesh (100-500 microns) for efficient sand separation.

- Coal washing: May require finer mesh (50-200 microns) depending on desired coal particle size and filtrate clarity.

- Mud pressing: Utilizes finer mesh (20-50 microns) to capture fine solids and achieve high dewatering efficiency.

4. Additional Considerations:

- Chemical Compatibility: Ensure the filter cloth material is resistant to the chemicals present in the slurry.

- Temperature Resistance: Choose a cloth suitable for the operating temperature range of your application.

- Cake Release Properties: Opt for a smooth weave or consider surface treatments for easier cake release in mud pressing.

Choosing the Right Filter Cloth – Specifications Table:

| Factor | Sand Washing | Coal Washing | Mud Pressing |

|---|---|---|---|

| Material | PET, PP | PET, Nylon | PP |

| Weave Pattern | Plain, Twill | Twill | Satin |

| Mesh Size (microns) | 100-500 | 50-200 | 20-50 |

| Chemical Compatibility | Neutral/Acidic Slurries | Varied | Alkalis/Solvents |

| Temperature Resistance | Moderate | Moderate-High | Moderate |

| Cake Release | Less Critical | Less Critical | Very Important |

Remember: This table provides a general guideline. Consulting with a filter cloth manufacturer like ChinaFilter is recommended to discuss your specific requirements and find the optimal solution for your sand washing, coal washing, or mud pressing application.

By considering these factors and consulting with a trusted filter cloth manufacturer, you can ensure optimal performance, minimize downtime, and maximize efficiency in your filtration processes.