The filter press cloth is a key component in any filtration process, helping to separate solids from liquids effectively. Selecting the right type of filter press cloth for your specific application is essential for optimizing filtration efficiency and achieving desired results. In this guide, we’ll explore the various types of filter press cloth materials, their unique properties, and the industries and applications where they are most commonly used.

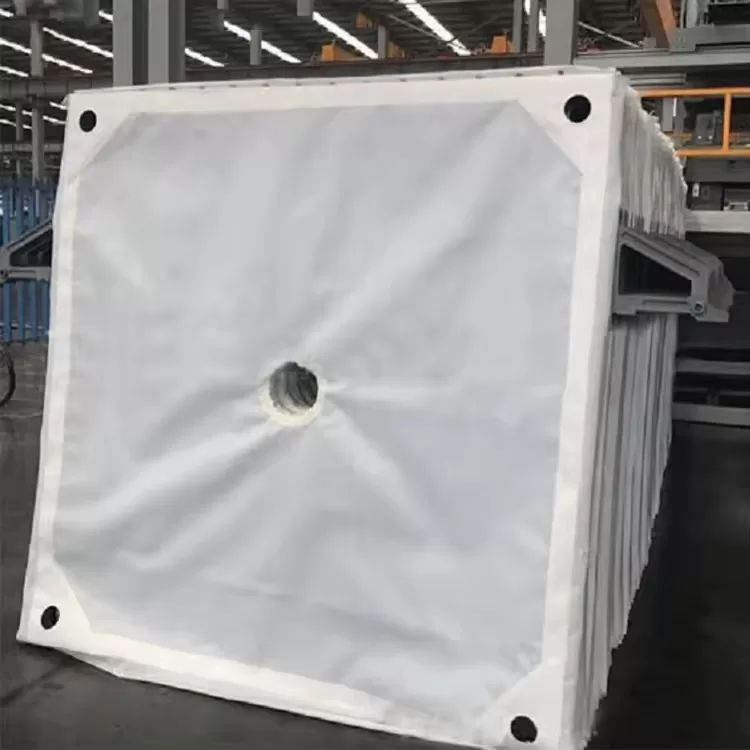

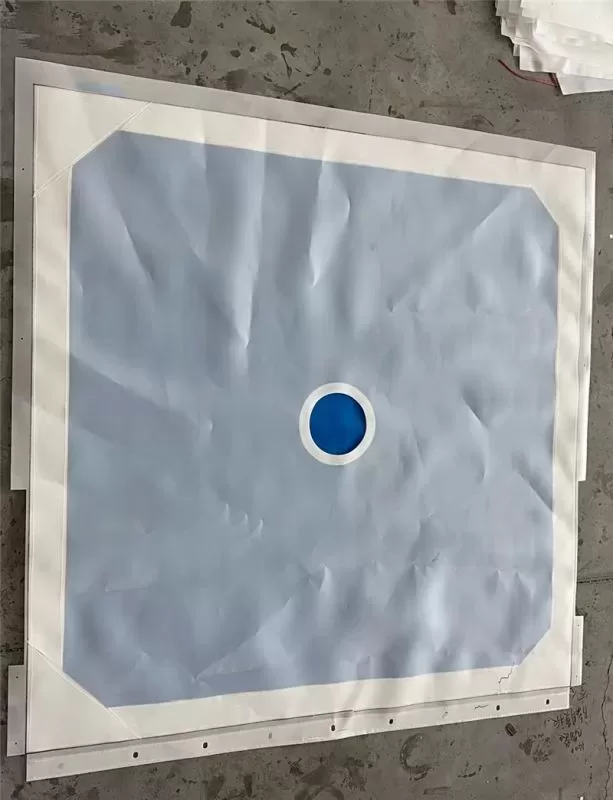

What is a Filter Press Cloth?

A filter press cloth is a permeable textile fabric that traps solid particles while allowing liquid to pass through during the filtration process. These cloths are used in a wide variety of industries, including mining, chemical processing, wastewater treatment, food production, and pharmaceuticals. The choice of cloth material depends on factors such as the type of slurry, chemical compatibility, and the operating conditions of the filtration system.

Types of Filter Press Cloth

There are several types of filter press cloth, each with specific characteristics that make them suitable for different filtration applications. Below are the most commonly used materials:

1. Polypropylene Filter Press Cloth

Polypropylene is one of the most widely used materials for filter press cloth due to its excellent chemical resistance and durability.

Key Features:

- Highly resistant to acids and chemicals

- Low moisture absorption

- Cost-effective

- Lightweight and easy to handle

Applications:

Polypropylene filter cloth is commonly used in industries dealing with aggressive chemicals, such as:

- Chemical processing: Ideal for processes involving acidic or caustic slurries.

- Mining: Used for mineral and ore processing.

- Wastewater treatment: Effective for filtering sludge in sewage treatment plants.

2. Polyester Filter Press Cloth

Polyester filter press cloth is known for its high tensile strength and resistance to abrasion, making it suitable for more demanding filtration processes.

Key Features:

- High strength and durability

- Good resistance to wear and tear

- Excellent water repellency

- Resistant to high-pressure filtration

Applications:

Polyester cloths are commonly used in industries where durability is key, such as:

- Mining and metallurgy: Effective for dewatering applications.

- Textile industry: Used for filtering dyes and pigments.

- Food processing: Suitable for juice filtration and sugar production.

3. Nylon Filter Press Cloth

Nylon is known for its exceptional strength and heat resistance, making it a popular choice for applications that involve high temperatures.

Key Features:

- High tensile strength

- Excellent heat resistance

- Good flexibility and abrasion resistance

- Resistant to certain solvents and oils

Applications:

Nylon filter cloths are typically used in industries requiring high-performance filtration, including:

- Oil filtration: Ideal for filtering oils and solvents.

- Automotive: Used for filtering coolant and lubricants.

- High-temperature processes: Suitable for filtration in applications with elevated temperatures.

4. Cotton Filter Press Cloth

Cotton is a natural and biodegradable material often used in industries requiring non-synthetic materials.

Key Features:

- Natural, biodegradable, and environmentally friendly

- Good filtration efficiency for certain food-grade applications

- Soft and flexible material

Applications:

Cotton filter cloths are primarily used in the food and beverage industry, where natural materials are preferred. Typical applications include:

- Food processing: Used for filtering edible oils, juices, and syrups.

- Beverage industry: Suitable for beer, wine, and cider filtration.

- Pharmaceutical industry: Used for certain biofiltration processes.

5. Polyvinylidene Fluoride (PVDF) Filter Press Cloth

PVDF filter cloth is known for its excellent chemical resistance and durability in harsh environments.

Key Features:

- Superior chemical and corrosion resistance

- High-temperature resistance

- Good durability and long service life

Applications:

PVDF filter press cloth is ideal for industries dealing with highly corrosive chemicals and extreme environments:

- Chemical processing: Used in filtration processes involving acids, alkalis, and solvents.

- Pharmaceuticals: Suitable for use in highly sterile environments.

- Mining: Effective in applications involving aggressive materials and high temperatures.

6. Polyamide (Nylon 6) Filter Press Cloth

Polyamide, also referred to as Nylon 6, is another strong and durable filter cloth material with excellent abrasion resistance.

Key Features:

- High durability

- Superior mechanical strength

- Good resistance to wear and chemicals

Applications:

Polyamide filter press cloth is used in industries that demand strong resistance to abrasion, such as:

- Mining and metallurgy: For dewatering and tailing filtration.

- Ceramics industry: Used for filtering ceramic slurries.

- Chemical manufacturing: Effective in filtering industrial chemicals.

How to Choose the Right Filter Press Cloth

Choosing the right filter press cloth depends on several factors, including the type of slurry, filtration requirements, and operating conditions. Here’s how to make the right choice:

1. Chemical Compatibility

Ensure that the material of the filter cloth is compatible with the chemicals present in the slurry. For example, polypropylene is highly resistant to acids, while nylon is better suited for oil filtration and high-temperature processes.

2. Filtration Efficiency

Different filter cloth materials have varying filtration efficiencies. If you need fine filtration, consider cloths with tighter weaves or smaller pore sizes, such as polyester or polypropylene.

3. Cake Discharge and Cleanability

The ability of the filter cloth to release the filter cake is crucial for efficiency. Cloths with smooth surfaces, like nylon, offer better cake discharge properties, while materials like polyester can be easily cleaned after filtration.

4. Temperature and Pressure Resistance

High-temperature applications require filter cloths made from materials like nylon or PVDF, which can withstand elevated temperatures and pressures. For low-pressure applications, materials like cotton or polyester may suffice.

Conclusion

Selecting the right filter press cloth is critical to the success of your filtration process. Whether you’re filtering aggressive chemicals, dewatering mining slurries, or separating fine particles in food processing, the correct filter cloth material can greatly improve efficiency, reduce downtime, and extend the life of your equipment.

By considering the specific characteristics of each filter cloth type—such as chemical resistance, durability, and filtration efficiency—you can choose the best option for your application, ensuring optimal performance and cost savings in the long run.

FAQs About Filter Press Cloth Types

1. What is the most versatile filter press cloth material?

Polypropylene is considered the most versatile material due to its chemical resistance, durability, and cost-effectiveness, making it suitable for a wide range of applications.

2. Which filter cloth is best for high-temperature applications?

Nylon and PVDF filter press cloths are best for high-temperature applications due to their excellent heat resistance.

3. Can I use cotton filter cloth for chemical processing?

Cotton filter cloth is not ideal for chemical processing due to its lower resistance to harsh chemicals. For such applications, polypropylene or polyester is a better choice.

By understanding the various types of filter press cloths and their applications, you can make informed decisions to improve your filtration process and achieve maximum efficiency.