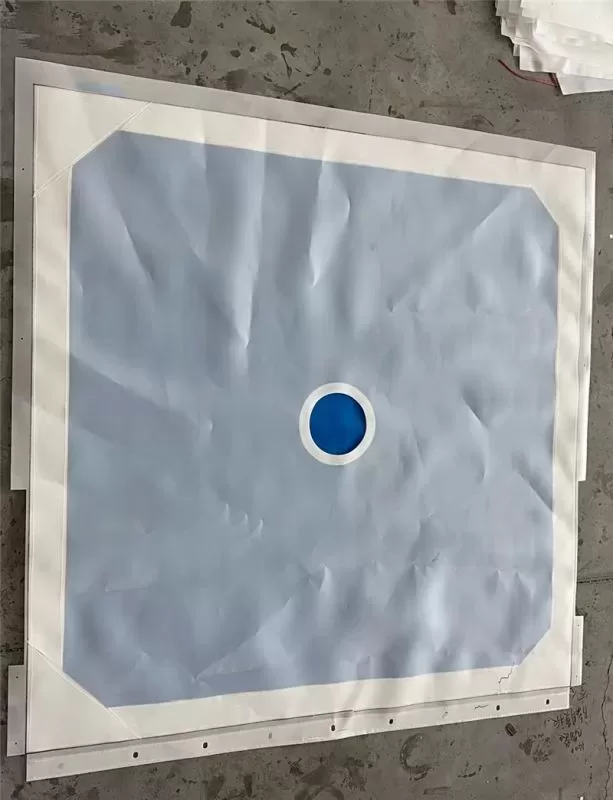

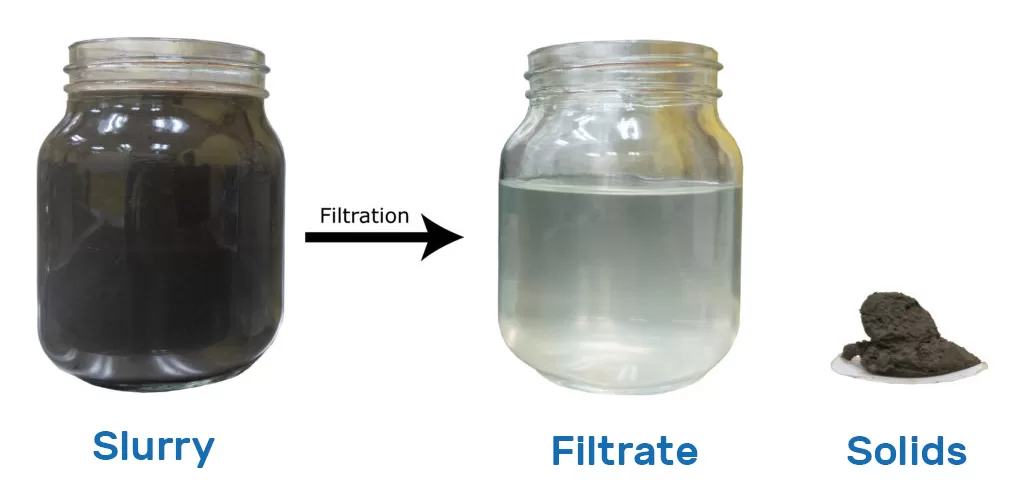

Selecting the optimal filter press cloth for activated carbon is crucial for maximizing filtration efficiency and minimizing downtime. This guide explores various filter cloth options suitable for pressing activated carbon, considering both material properties and operational factors.

Key Considerations for Activated Carbon Filter Press Cloths:

- Activated Carbon Characteristics: Particle size, abrasiveness, and chemical compatibility with the cloth material all play a role.

- Filter Press Operating Conditions: Factors like pressure, temperature, and desired filtrate clarity influence cloth selection.

Common Filter Cloth Options for Activated Carbon:

1. Polyester Filter Cloth:

Subtypes: Polyester staple fiber and long fiber

Properties:

- Acid and weak alkali resistant

- Wear and corrosion resistant

- Good resilience, poor conductivity

Advantages:

- High cost-performance

- Excellent wear resistance (long fiber)

Disadvantages:

- Poor air permeability (staple fiber)

- Difficult cake discharge (staple fiber)

2. Polypropylene Filter Cloth:

Subtypes: Polypropylene short fiber and long fiber

Properties:

- Acid and alkali resistant

- Filtration performance varies with fiber length (short for powder, long for pressure)

Advantages:

- Good for powder and pressure filtration (depending on fiber length)

- Medium-thin and thick options for diverse needs

Disadvantages: Filtration performance can be lower than other options

3. Nylon Filter Cloth:

Properties:

- High strength and wear resistance

- Resistant to strong alkali and weak acid

Advantages: Excellent strength and durability

Disadvantages:

- Not light-resistant (discolors and weakens in sunlight)

- Not suitable for long-term sunlight exposure

Additional Selection Factors:

- Filtration Accuracy: Choose a pore size that effectively retains activated carbon particles.

- Filter Cake Peeling: Select a cloth that facilitates easy cake discharge and cleaning.

- Chemical Stability: Ensure compatibility between the cloth and the activated carbon/process chemicals.

- Strength and Durability: The cloth should withstand pressure, friction, and offer a long service life.

Optimizing Your Choice:

- Material Filtration Experiment: Conduct a small-scale test using your specific activated carbon to observe filtration and cake discharge with different cloths.

- Supplier Expertise: Consult your filter cloth supplier for recommendations based on your application details.

Conclusion:

By carefully considering the factors outlined above, you can select the most suitable filter press cloth for your activated carbon application. This will ensure optimal filtration performance, minimize downtime, and maximize the efficiency of your operation.