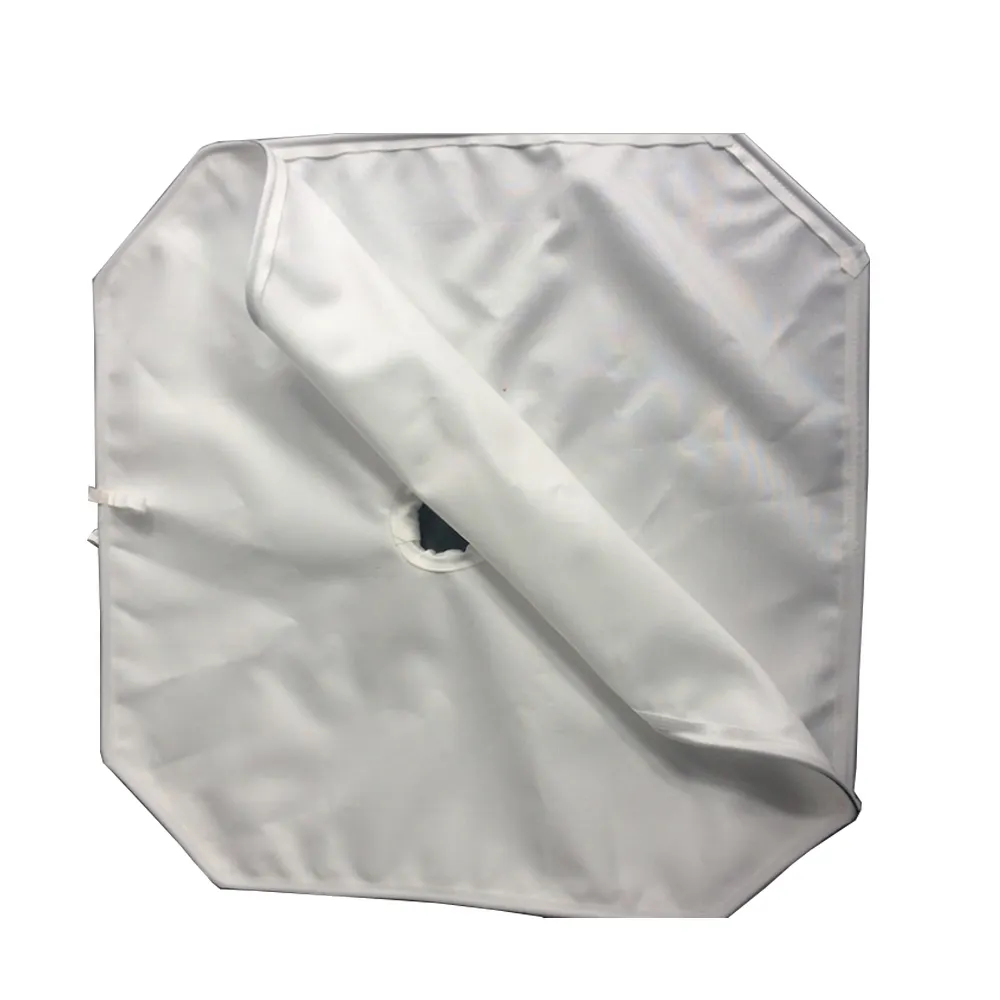

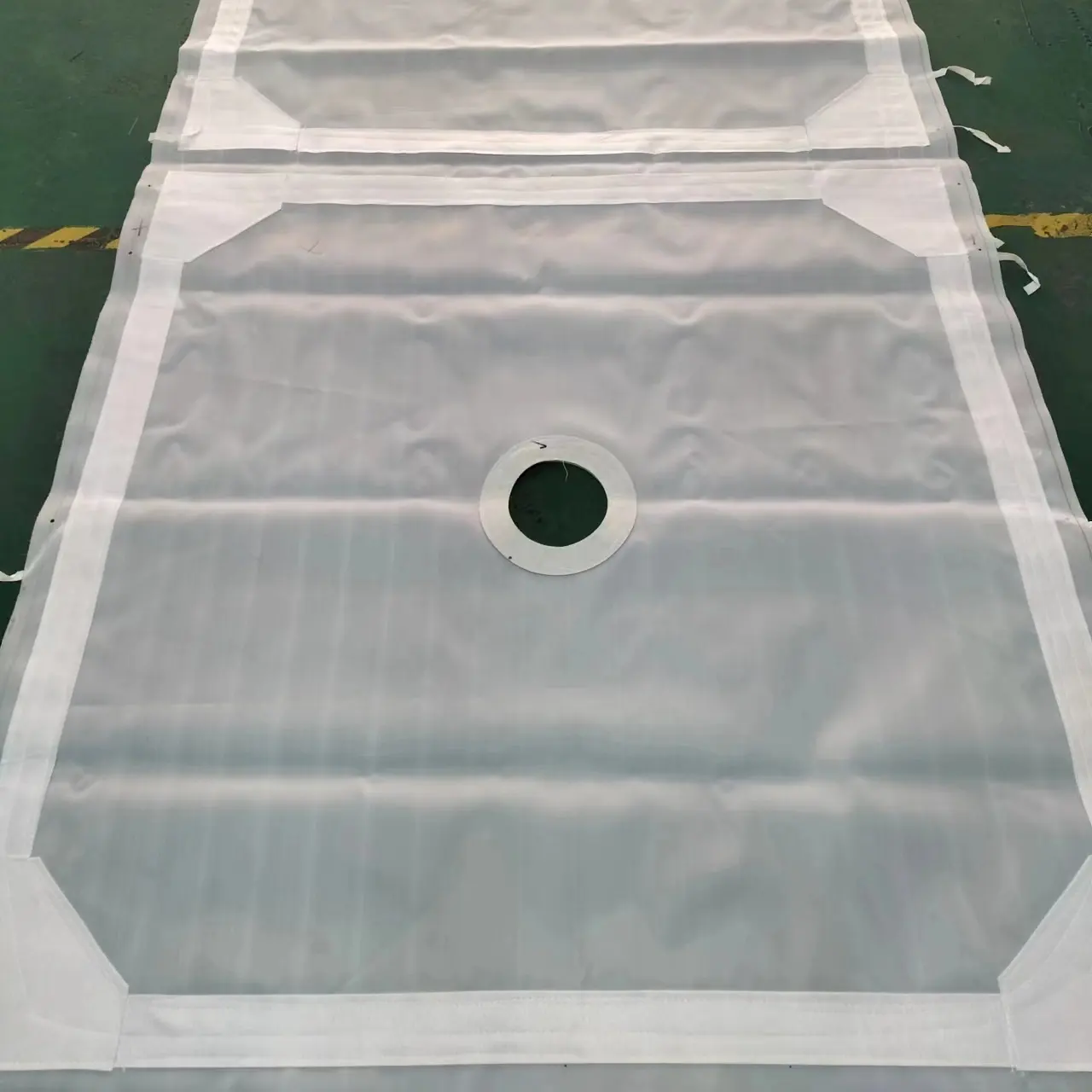

The filter press cloth is a versatile tool used across a wide range of industries for separating solids from liquids in filtration processes. While its primary role is in traditional filtration, innovations in the design and application of filter press cloths have expanded their utility in industrial processes. This article explores the innovative uses of filter press cloth in modern industries, demonstrating how technological advancements have revolutionized filtration practices.

The Role of Filter Press Cloth in Industrial Filtration

A filter press cloth serves as a permeable barrier that separates solid particles from liquid during filtration. Its efficiency in capturing fine particles while allowing the liquid to pass through makes it invaluable in many industries. From wastewater treatment to food processing, filter press cloths play a vital role in improving operational efficiency, reducing waste, and promoting environmental sustainability.

Traditional Uses of Filter Press Cloth

Historically, filter press cloths have been used in industries such as:

- Mining: For dewatering mineral slurries and tailings.

- Food and beverage: For filtering oils, juices, and syrups.

- Chemical manufacturing: For separating chemicals from solutions in production processes.

- Pharmaceuticals: For biofiltration and sterile separation processes.

While these applications remain essential, modern industries have found innovative ways to use filter press cloths in unconventional settings.

Innovative Uses of Filter Press Cloth in Modern Industrial Processes

Advancements in material technology and custom filter press cloth designs have opened new avenues for their use in various industrial sectors. Below are some of the innovative applications of filter press cloths in contemporary processes:

1. Filtration in 3D Printing

In the rapidly evolving world of 3D printing, filter press cloths have found a unique application. The production of intricate 3D-printed components involves the use of resins and powders, which require precision filtration to remove impurities and ensure a smooth finish. High-performance filter press cloths are now used to:

- Filter liquid resins: Removing contaminants from resins in stereolithography (SLA) printing.

- Powder recovery: In powder bed fusion processes, filter press cloths assist in recovering unused powders, enhancing material efficiency and reducing waste.

2. Biomass and Biofuel Production

As the demand for renewable energy continues to grow, the production of biofuels and biomass has become a key focus. Filter press cloths are now being used in biofuel production to:

- Filter biomass slurries: Helping to separate solid organic matter from the liquid byproducts in biomass fermentation.

- Algae harvesting: Innovative filter press cloth designs are used to filter and collect algae, which are converted into biofuels.

By improving filtration in biofuel production, filter press cloths help enhance sustainability and promote greener energy solutions.

3. Advanced Wastewater Treatment

One of the most innovative uses of filter press cloths is in advanced wastewater treatment systems. In industries such as municipal water treatment, agriculture, and chemical manufacturing, these cloths are now used to:

- Filter microplastics: Custom filter press cloths can be designed to capture microscopic pollutants like microplastics, which are increasingly present in water systems.

- Remove heavy metals: In industrial wastewater, filter press cloths are used to capture heavy metals, ensuring the treated water is safe for reuse or discharge.

These innovations not only improve the efficiency of wastewater treatment processes but also contribute to environmental sustainability by reducing water pollution.

4. Filtration in Lithium Battery Production

With the rise of electric vehicles (EVs) and renewable energy storage, the demand for lithium batteries has surged. Filter press cloths now play a crucial role in the production of these batteries by:

- Filtering lithium salts: During the lithium extraction process, filter press cloths help in purifying lithium salts from brine or ore.

- Battery slurry filtration: The slurry used in manufacturing lithium-ion battery electrodes requires precise filtration to remove impurities, ensuring the final product’s quality.

This innovative use of filter press cloths is helping to advance the battery manufacturing process, supporting the shift to cleaner energy.

5. Filtration in Additive Manufacturing

Additive manufacturing, commonly known as 3D printing, also benefits from innovations in filter press cloth technology. In powder-based additive manufacturing processes, these cloths are used to recover fine metallic powders and ensure precise filtration of solvents, which are vital for producing high-quality printed components.

6. Oil and Gas Industry Innovations

The oil and gas industry has long relied on filter press cloths for traditional filtration processes, such as oil refining and gas purification. However, new uses of filter press cloths are emerging, including:

- Enhanced oil recovery (EOR): Advanced filtration methods utilizing filter press cloths help in separating oil from water in challenging environments, enhancing recovery rates.

- Shale gas extraction: During fracking, filter press cloths are employed to filter fine particles from the slurry, improving operational efficiency and reducing environmental impact.

These innovations are helping oil and gas producers meet higher environmental standards while maintaining operational efficiency.

7. Pharmaceutical and Biotechnology Applications

In the pharmaceutical and biotechnology sectors, the need for high-precision filtration has driven innovative uses of filter press cloths. Some examples include:

- Protein separation: Filter press cloths are used in the production of protein-based drugs, ensuring that the end product is free from impurities.

- Cell culture filtration: In biotechnology, filter press cloths are used to separate cells from liquid media in bioreactors, helping to produce vaccines, enzymes, and other biopharmaceuticals.

By offering precise filtration in these highly regulated industries, filter press cloths play an essential role in ensuring product quality and safety.

Key Benefits of Using Filter Press Cloth in Innovative Applications

The expansion of filter press cloth applications across industries offers numerous benefits, including:

- Improved filtration efficiency: Innovative filter cloth designs can capture finer particles, improving overall filtration performance.

- Enhanced sustainability: Filter press cloths reduce waste and energy consumption in processes like biofuel production and advanced wastewater treatment.

- Cost savings: By improving filtration precision and reducing downtime, filter press cloths help lower operational costs in industrial processes.

- Versatility: Filter press cloths are adaptable to a wide range of materials and industries, making them a valuable asset for industrial innovation.

Conclusion

The filter press cloth is no longer limited to traditional filtration roles; it has evolved into a versatile and innovative tool used in a wide range of industrial processes. From biofuel production to advanced wastewater treatment and lithium battery manufacturing, filter press cloths have proven their value in improving operational efficiency, reducing environmental impact, and driving industrial advancements.

As industries continue to innovate, the role of the filter press cloth is expected to grow, with new materials and designs allowing for even greater efficiency and versatility. By incorporating these innovative uses into industrial processes, companies can optimize their operations and contribute to a more sustainable future.

FAQs About Innovative Uses of Filter Press Cloth

1. How is filter press cloth used in biofuel production?

Filter press cloths are used to separate biomass solids from liquids during biofuel production, improving efficiency and product yield.

2. Can filter press cloths capture microplastics in wastewater treatment?

Yes, custom-designed filter press cloths can effectively capture microplastics and other fine pollutants in advanced wastewater treatment systems.

3. What role does filter press cloth play in lithium battery production?

Filter press cloths are used to filter lithium salts and battery slurries, ensuring the purity and quality of lithium-ion battery components.

By embracing these innovations, industries can achieve more efficient and sustainable filtration processes, leveraging the versatility of filter press cloths for the future of industrial development.