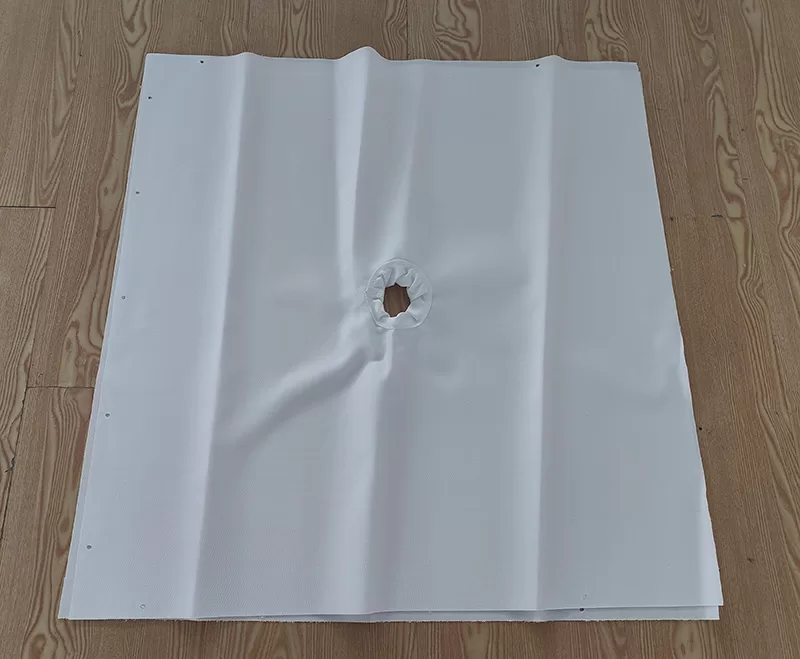

Choosing the right filter press cloth material is crucial for optimizing your filtration process. Different materials offer distinct advantages and disadvantages, so understanding their properties is key to achieving efficient and cost-effective results. This guide compares the most common filter press cloth materials across various factors:

1. Chemical Resistance:

- Polypropylene (PP): Good resistance to acids and alkalis, but struggles with organic solvents.

- Polyester (PET): Tolerates some acids and alkalis, but performance weakens in strong solutions compared to PP.

- Nylon (PA): Handles alkalis well, but susceptible to strong acids.

2. Temperature Adaptability:

- Polypropylene (PP): Stable operation generally below 90°C.

- Polyester (PET): Withstands temperatures up to around 150°C.

- Nylon (PA): Typically functions effectively around 100°C.

3. Wear Resistance:

- Nylon (PA): Excellent wear resistance, ideal for handling materials with high solid particle content.

- Polyester (PET): Offers good wear resistance.

- Polypropylene (PP): Relatively weak in wear resistance.

4. Filtration Accuracy:

- Nylon (PA): Larger pores result in lower filtration accuracy.

- Polyester (PET): Achieves higher filtration precision.

- Polypropylene (PP): Offers moderate filtration accuracy.

5. Water Permeability:

- Polypropylene (PP): Excellent water permeability, allowing for fast filtrate discharge.

- Nylon (PA): Average water permeability.

- Polyester (PET): Water permeability varies depending on the specific weave structure.

6. Price:

- Polypropylene (PP): Generally the most affordable option.

- Polyester (PET): Moderate price point.

- Nylon (PA): Relatively expensive.

7. Service Life:

- Nylon (PA): Superior wear resistance translates to a longer lifespan.

- Polyester (PET): Offers a long service life, potentially slightly shorter than nylon.

- Polypropylene (PP): Has a comparatively shorter service life.

Choosing the Best Material for Your Needs:

Consider these factors when selecting a filter press cloth material:

- Filtration process requirements: The type of slurry being filtered, desired filtrate clarity, and cake release properties.

- Operating conditions: Temperature, pressure, and chemical compatibility with the materials being processed.

- Cost considerations: Balancing performance needs with budgetary constraints.

Additional Tips:

- Consult with a filter press cloth manufacturer for expert recommendations based on your specific application.

- Conduct filtration trials with different cloth materials to determine the optimal choice for your process.

- Implement proper cleaning and storage practices to extend the life of your filter press cloths.

By understanding the unique properties of various filter press cloth materials, you can make an informed decision that ensures optimal performance and efficiency in your filtration operations.