When it comes to optimizing the performance of your filter press, one of the most critical components is the filter press cloth. Choosing the right filter cloth is crucial to achieving effective filtration, prolonging equipment life, and minimizing operational costs. In this guide, we’ll explore the key factors to consider when selecting a filter press cloth, ensuring that you make an informed decision tailored to your specific industrial needs.

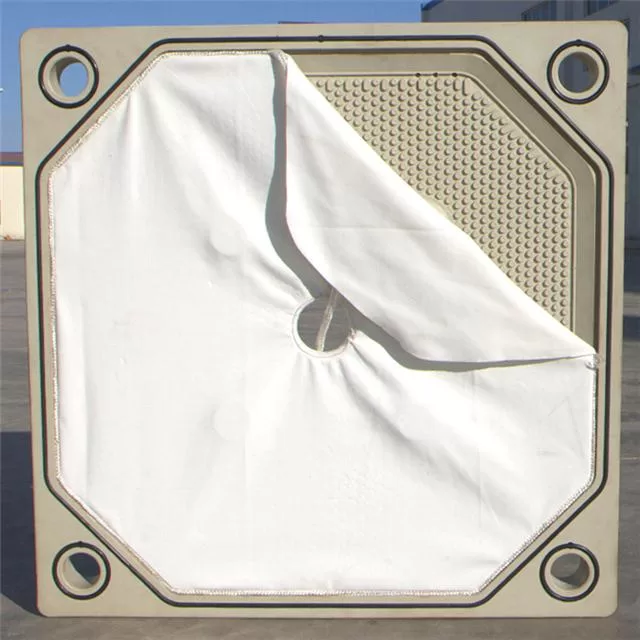

What is a Filter Press Cloth?

A filter press cloth is a specialized fabric used in filter press machines to separate solids from liquids during the filtration process. These cloths come in a variety of materials, weaves, and specifications to cater to different industries such as mining, chemical processing, wastewater treatment, and food production. The cloth acts as a barrier, allowing liquids to pass through while trapping solid particles.

Factors to Consider When Choosing Filter Press Cloth

Selecting the right filter press cloth requires an understanding of several critical factors, including the nature of your slurry, the filtration cycle, and operational conditions. Below are the key considerations:

1. Material Compatibility

The material of the filter cloth should be compatible with the slurry you are filtering. Some common materials used for filter press cloths include:

- Polypropylene: Highly resistant to chemicals and acids, making it ideal for chemical and pharmaceutical industries.

- Polyester: Offers excellent tensile strength and is resistant to abrasion, suitable for various industrial applications.

- Cotton: Typically used for food processing due to its natural and biodegradable properties.

- Nylon: Known for its durability and heat resistance, often used in high-temperature applications.

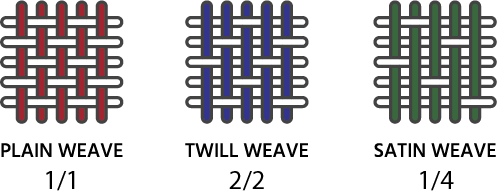

2. Weave Pattern

The weave pattern of the filter press cloth impacts its filtration efficiency and cake release. Common weave types include:

- Plain Weave: Provides uniform filtration with tight pore sizes, ideal for fine particle filtration.

- Twill Weave: Offers better cake release properties and is less prone to clogging, suitable for heavy-duty applications.

- Satin Weave: A smoother surface that enhances cake release and is easier to clean, often used in food and pharmaceutical industries.

3. Micron Rating

The micron rating indicates the size of particles that the filter cloth can capture. A lower micron rating captures finer particles but may increase filtration time, while a higher rating allows faster filtration but with larger particle retention. Choose a micron rating based on the type of solids in your slurry.

4. Cake Discharge and Cleanability

Efficient cake discharge is essential to maintain optimal performance and reduce downtime. A filter cloth with good cake release properties ensures minimal residue remains on the cloth after filtration. Additionally, consider whether the cloth is easy to clean or requires frequent replacements to minimize operational costs.

5. Operating Conditions

The temperature and pressure of your filtration process are critical factors in choosing the right filter cloth. High-pressure applications require more durable materials like polyester or nylon, while high-temperature processes may require specialized heat-resistant cloths.

6. Chemical Resistance

If your filtration process involves aggressive chemicals, ensure the filter cloth material can withstand these without degrading. Polypropylene, for instance, is highly resistant to acids and chemicals, making it ideal for industries handling harsh substances.

Common Types of Filter Press Cloth Materials

Understanding the materials used in filter press cloths is essential to select the right one for your specific filtration needs. Here are the most commonly used materials:

- Polypropylene: Most popular due to its chemical resistance and cost-effectiveness.

- Polyester: Strong and resistant to wear, good for heavy-duty applications.

- Cotton: Environmentally friendly and used in industries requiring biodegradable materials.

- Nylon: Known for its strength and temperature resistance, commonly used in high-temperature applications.

Customizing Your Filter Press Cloth

In some cases, off-the-shelf filter press cloths may not meet the unique requirements of your filtration process. Manufacturers offer custom filter press cloths tailored to your specific needs, such as:

- Specialized coatings for enhanced chemical resistance

- Custom weaves for improved cake release or filtration efficiency

- Unique sizes and shapes to fit non-standard filter press plates

By customizing your filter cloth, you can optimize performance, reduce downtime, and lower operational costs.

Maintenance and Care Tips for Filter Press Cloth

Proper maintenance of your filter press cloth is key to extending its lifespan and ensuring consistent performance. Here are some essential care tips:

- Regular Cleaning: Periodic cleaning prevents clogging and ensures efficient filtration. Use appropriate cleaning agents based on the material of the cloth.

- Monitor Wear and Tear: Over time, filter cloths can degrade. Inspect regularly for any signs of wear, including thinning or tears.

- Replacement Schedule: Follow a proactive replacement schedule to avoid unexpected breakdowns and ensure optimal filtration results.

Conclusion

Choosing the right filter press cloth is crucial to the efficiency and success of your filtration process. By considering factors such as material compatibility, weave pattern, micron rating, and operating conditions, you can select a filter cloth that meets your specific industrial requirements. Proper care and maintenance further extend the life of your filter cloth, optimizing performance and minimizing operational costs.

By making an informed decision, you ensure smoother operations, reduced downtime, and improved filtration efficiency in your plant.

FAQs About Filter Press Cloth

1. How often should I replace my filter press cloth?

The frequency of replacement depends on factors such as the material used, the nature of the slurry, and operational conditions. Regular inspection can help determine when it’s time for a replacement.

2. Can I clean and reuse a filter press cloth?

Yes, filter press cloths can often be cleaned and reused, provided they are not damaged. Regular cleaning ensures efficient filtration and extends the cloth’s lifespan.

3. What is the best material for a filter press cloth?

The best material depends on your specific application. For chemical resistance, polypropylene is a popular choice, while polyester is ideal for heavy-duty applications requiring durability.

By following this guide, you’ll be able to choose the perfect filter press cloth that aligns with your operational needs and enhances the efficiency of your filtration process.

We’re leading filter press cloth manufacturer in China, please feel free to contact us for your filter press cloth needs.