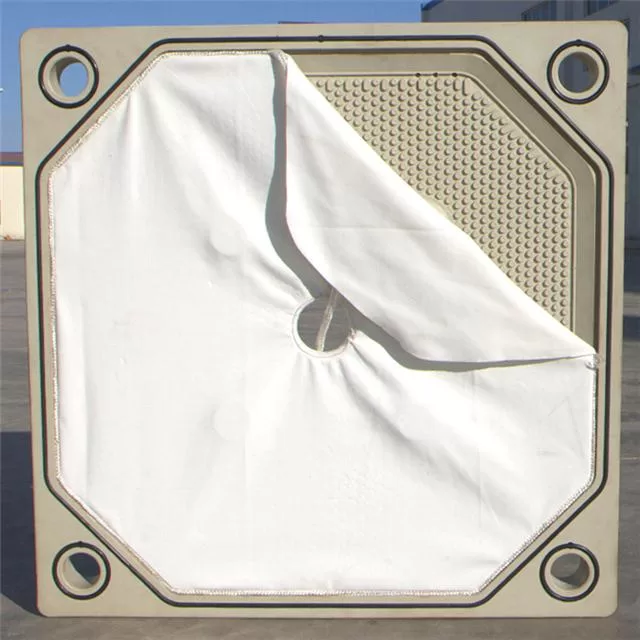

Choosing the right filter cloth is key to optimizing performance in diaphragm filter presses, which are essential tools for separating solids from liquids. In this guide, we’ll explore the most common industrial filter cloths used with diaphragm presses and help you select the best one for your application.

Types of Industrial Filter Cloths for Diaphragm Filter Presses:

Polyester Filter Cloth:

- Boasts high strength, wear resistance, and excellent resistance to acids and alkalis.

- Versatility makes it suitable for most solid-liquid separation applications in diaphragm filter presses.

Polypropylene Filter Cloth:

- Stands out for its low density and lightweight construction, ideal for applications where weight is a concern.

- Offers good acid and alkali resistance as well.

Monofilament Filter Cloth:

- Known for its uniform pore size, translating to high filtration accuracy.

- Resists clogging, making it suitable for processes demanding precise filtration.

Non-Woven Filter Cloth:

- Offers excellent air permeability and low filtration resistance.

- Well-suited for applications where minimizing filtration resistance is a priority.

Choosing the Right Cloth:

Selecting the most appropriate filter cloth hinges on several factors:

- Nature of the Material: The type of material being filtered significantly impacts the choice. Consider factors like particle size, abrasiveness, and chemical properties.

- Filtration Accuracy Requirements: The desired level of filtrate clarity dictates the pore size and filtration efficiency needed in the filter cloth.

- Filtration Resistance Requirements: Some processes prioritize minimizing resistance to filtrate flow. In such cases, non-woven cloths might be ideal.

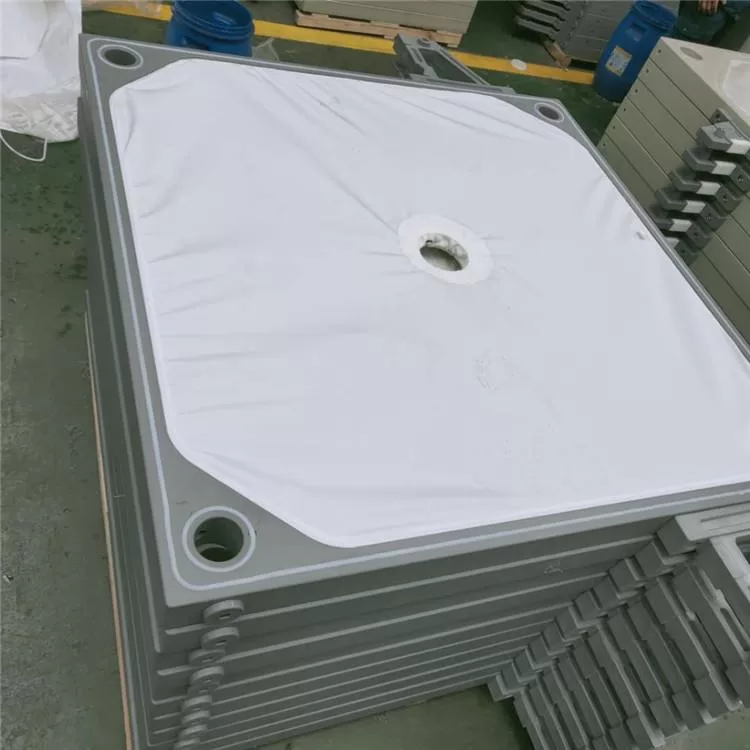

Beyond Selection: Installation and Maintenance

Proper installation and maintenance are equally important for maximizing filter cloth performance and lifespan. Here are some key practices:

- Follow filter cloth manufacturer‘s recommendations for installation to ensure proper fit and avoid damage.

- Regular cleaning is essential to prevent clogging and maintain optimal filtration efficiency.

- Inspect the filter cloth regularly for signs of wear and tear. Replace it promptly to avoid compromised performance or potential malfunctions.

Conclusion

By understanding the different types of filter cloths and carefully considering the factors mentioned above, you can select the optimal cloth for your diaphragm filter press application. Remember, proper installation and maintenance practices will further ensure the success of your filtration process.