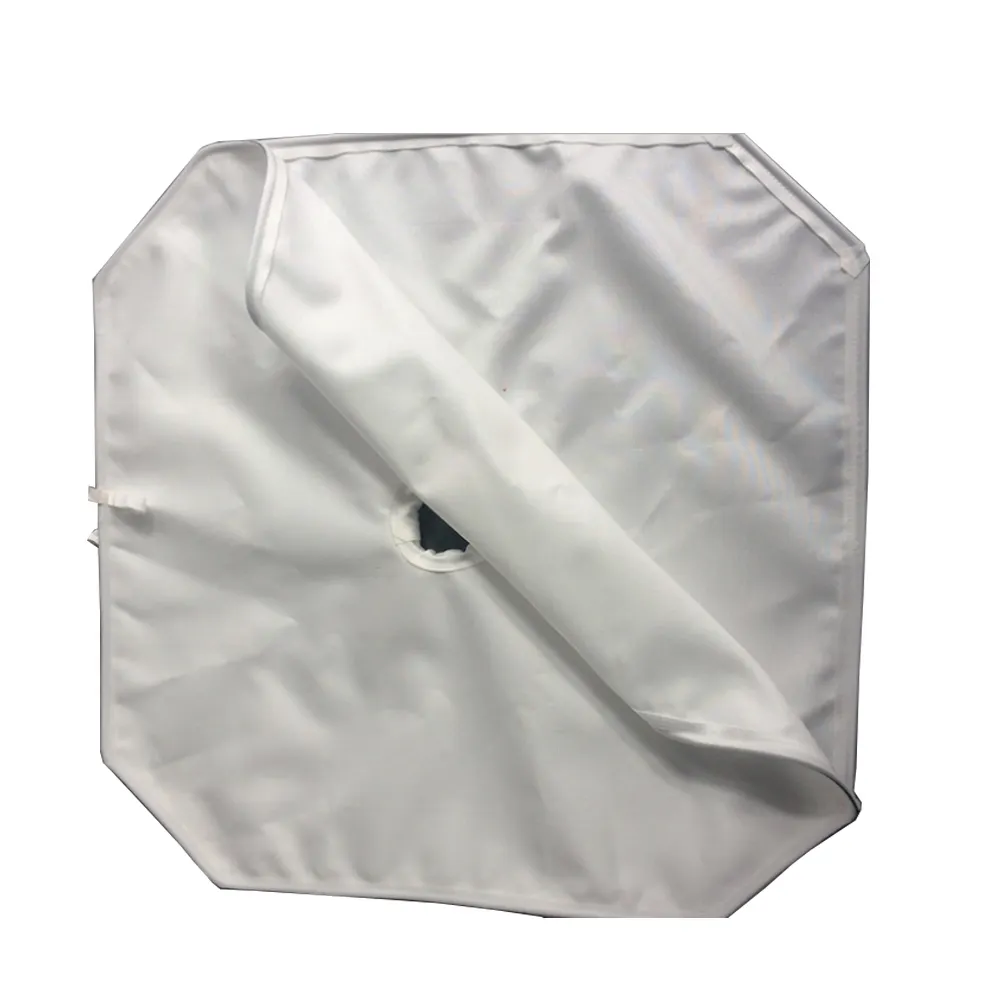

The filter cloth is the heart of your filter press, directly impacting its efficiency and effectiveness. Selecting a high-quality cloth is crucial for optimal filtration results and long-term cost savings. But how do you judge the quality of a filter press cloth? Here’s a comprehensive guide to help you make informed decisions:

1. Material Matters:

- Polypropylene: Known for excellent acid and alkali resistance, ideal for diverse filtration applications.

- Polyester: Offers exceptional strength and wear resistance, perfect for handling abrasive materials.

- Other options: Consider nylon for specific chemical compatibility or Nomex for high-temperature filtration.

2. Weaving Perfection:

Look for a filter cloth with uniform and tight weaving. This ensures:

- Superior filtration effect: Captures desired particles while allowing filtrate to pass through efficiently.

- Reduced leakage and clogging: Prevents filtrate contamination and maintains smooth operation.

3. Pore Size and Distribution:

Pore size and distribution are critical for filtration accuracy. Use a magnifying glass or microscope to assess:

- Uniformity: Ensures consistent filtration performance throughout the cloth.

- Right size for your application: Match pore size to the particles you want to capture for optimal results.

4. Strength You Can Trust:

High-quality filter cloths boast excellent tensile strength. This translates to:

- Resistance to tearing and deformation: Ensures the cloth withstands pressure during filtration.

- Longer lifespan: Durable cloths require less frequent replacements, saving you money.

5. Corrosion Resistance: Chemical Compatibility

Consider the chemical properties of the material you’ll be filtering. Choose a cloth with appropriate resistance to:

- Acids and alkalis: Crucial for handling various industrial slurries.

- Organic solvents: Ensures compatibility with specific chemical processes.

6. Water Permeability: The Flow Factor

Water permeability directly impacts filtration efficiency. You can assess this through:

- Manufacturer data: Look for water permeability specifications.

- Simulated filtration experiments: Test the cloth’s performance with a representative liquid.

7. Surface Matters: Smoothness for Efficiency

A smooth surface on the filter cloth offers several advantages:

- Enhanced filtration: Promotes efficient passage of filtrate.

- Reduced residue: Makes it easier to remove filtered materials, minimizing buildup.

8. Service Life: Durability for Long-Term Value

- Manufacturer data: Review the expected service life provided by the manufacturer.

- User feedback: Look for real-world experiences from other users to gauge cloth longevity.

9. Cleaning Performance: Easy Maintenance, Lower Costs

A filter cloth that’s easy to clean translates to:

- Reduced downtime: Faster cleaning minimizes interruptions in your filtration process.

- Improved cost-efficiency: Lower cleaning costs mean more savings in the long run.

10. Dimensional Accuracy: Precise Fit for Optimal Performance

Ensure the filter cloth’s dimensions match your filter press specifications. This prevents:

- Leakage: A properly sized cloth guarantees a secure fit and efficient filtration.

- Installation issues: Accurate dimensions simplify installation and ensure smooth operation.

By considering these ten key factors, you can confidently choose the perfect filter cloth for filter press. Remember, a high-quality cloth optimizes filtration efficiency, minimizes downtime and maintenance costs, and ultimately contributes to a more profitable and productive filtration process.